Are there any future applications or trends within power electronics that are particularly exciting?

IL: The overriding trend in power electronics for many decades has been what we call SWaP-C — minimising size, weight, power (loss) and cost and trying to optimise each one. Up until now, this has been done in a non-organised way with lots of trial and error.

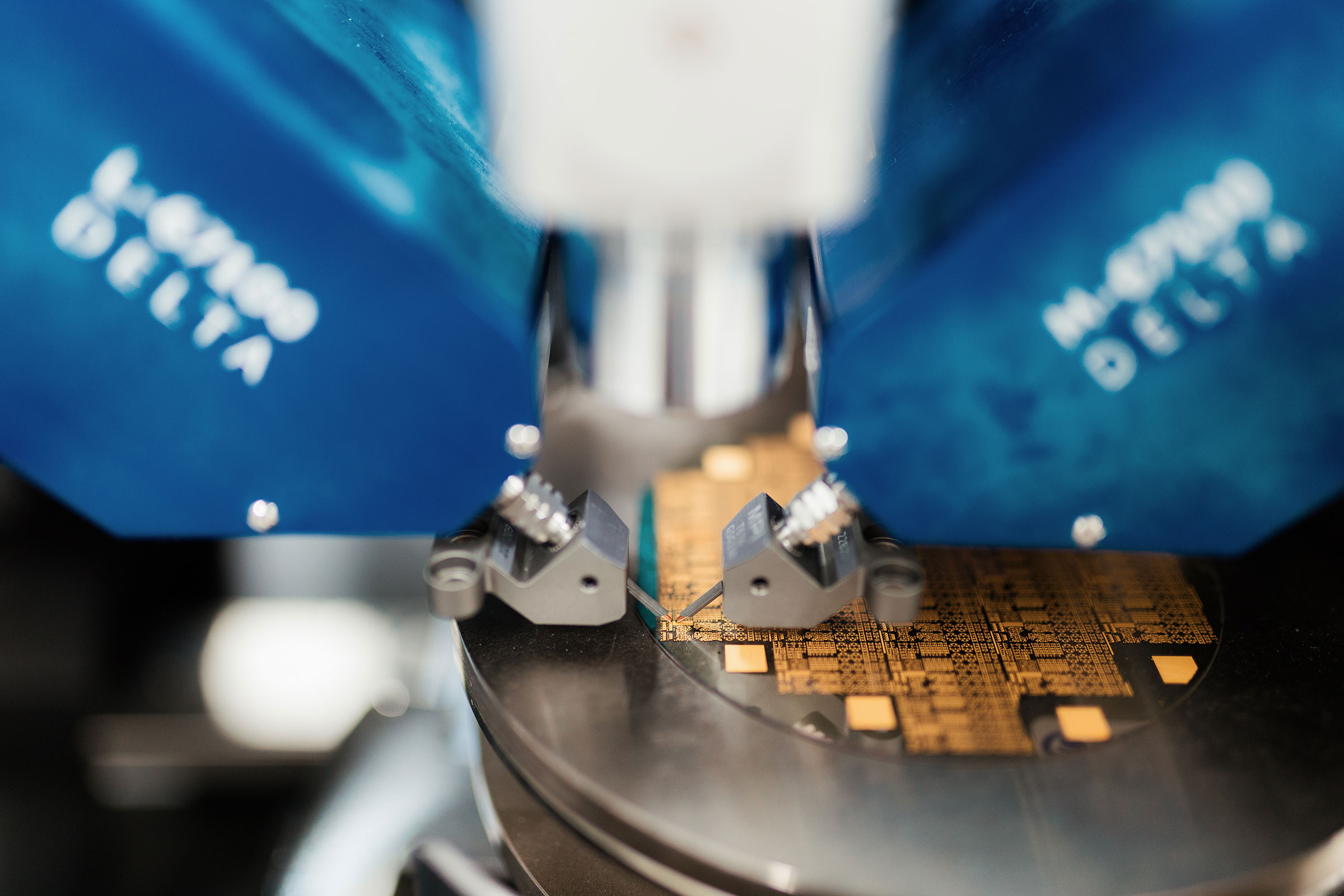

What we’re seeing now is a move towards automating this process by taking advantage of machine learning and artificial intelligence (AI) techniques. This will allow us to design power converters in a more systematic and automated way so that the right components are chosen for optimised circuit topology for each specific application. Ultimately, we will be able to make power converters more efficient using less materials and at a lower cost than before.

We call this multi-objective optimisation. It’s really exciting and something that we’re heavily involved in at CSA Catapult.

What are the challenges or obstacles facing the industry, and how might they prevent us from reaching our Net Zero targets? And what are we doing to solve them?

IL: One big challenge for power electronics, especially in the energy distribution market, is the required lifetime of a power converter.

The big and bulky passive transformers we currently use have been doing a good job for 40 or 50 years. Trying to replicate that longevity with power electronics is challenging because these devices are much smaller and contain many, many individual components to make a system. And just from a probability point of view, components can fail, so this is a really big challenge.

Staying competitive is also a challenge, especially with many different sectors requiring power electronics and developing so quickly. This is where AI will have the biggest impact, allowing us to search and simulate different solutions and combinations in just a matter of minutes compared to weeks and months.

Looking to the future, what does the UK need to do to capitalise on our expertise and push us towards our Net Zero targets?

IL: It’s positive to see the UK government is aligned with the UK’s strength in compound semiconductors, and that provides many opportunities for the sector in the UK. The UK is very strong in academic research in compound semiconductors as well.

We can use this to our advantage and position the UK as leading the world in compound semiconductors, from the design and manufacturing of devices, the packaging and the power converters for many different markets.

All of this will help to grow the UK economy and achieve Net Zero targets.

However, to fully develop the industry at scale, future investment in the overall supply chain will be required.

And what role can CSA Catapult play in this?

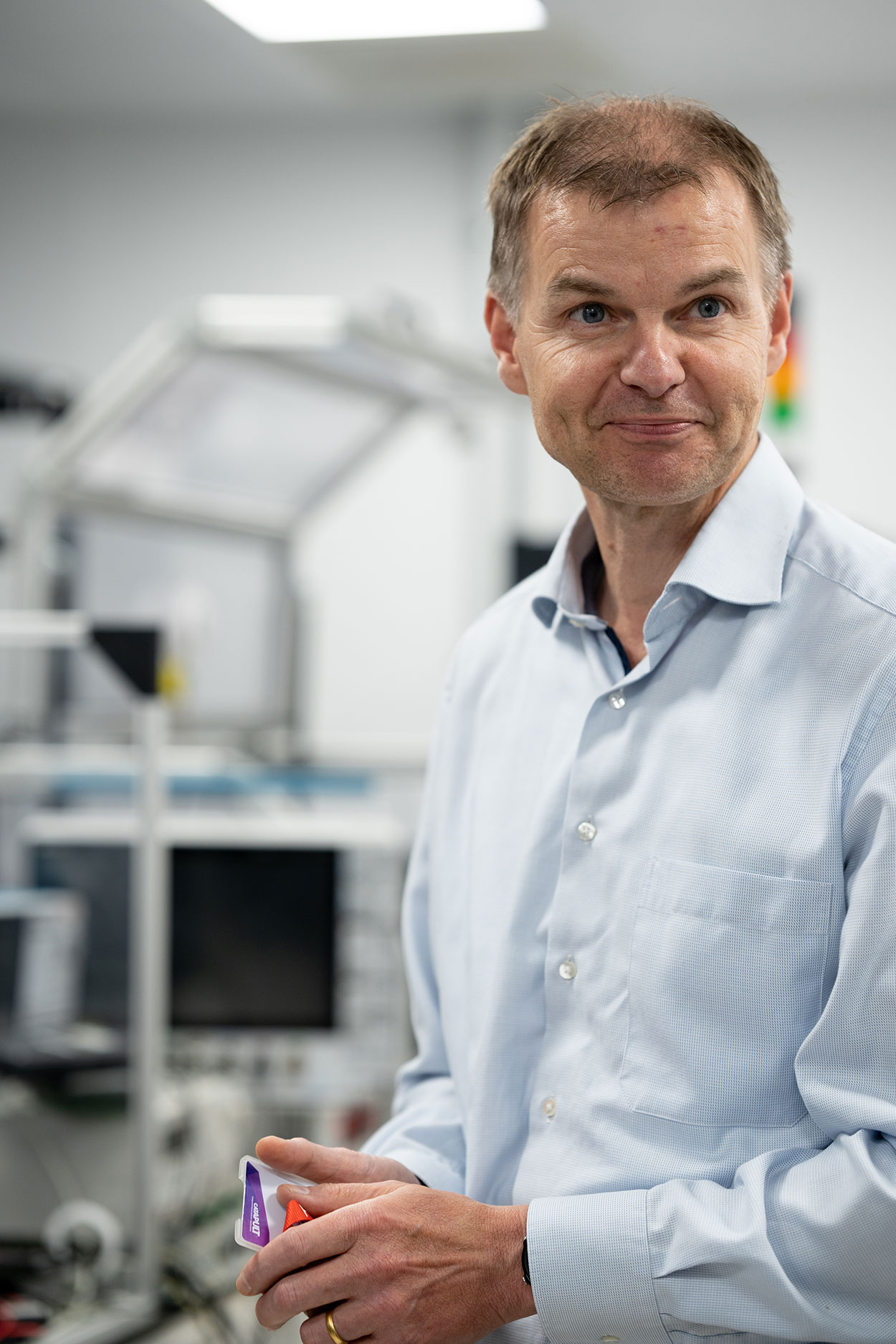

IL: The CSA Catapult supports the UK industry in developing the technical innovations required. We also convene and influence for the industry.

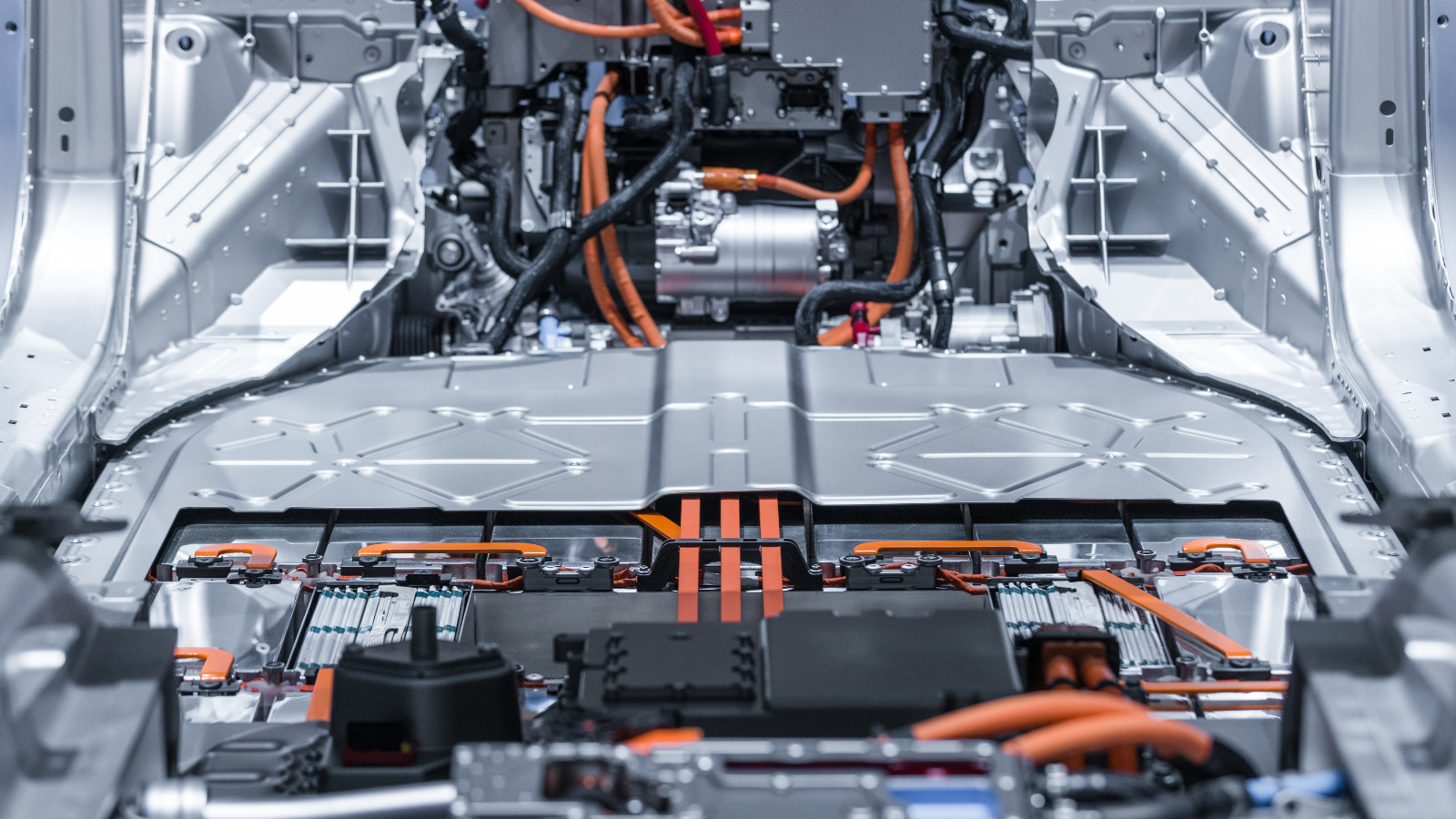

In the power electronic sector, we have been working very closely with our packaging team at CSA Catapult and together we’ve had over 20 collaborative research and development projects that have supported the industry in evaluating different solutions for the transportation, energy and data centre markets to fully exploit what compound semiconductor components can do.

And finally, how optimistic are you that the UK can reach its Net Zero targets and how important will compound semiconductors and power electronics be to achieving this?

IL: I’m very optimistic based on the technical strengths in the UK, within academia and industry.

I’m also optimistic about future government investment into this area to build a supply chain that can establish the UK as a global leader in compound semiconductors.